Upgrades and Retrofit

Construction

Upgrades and Retrofit

Construction

Fiber Reinforced Polymer (FRP)

Enlargement and Overlay Systems

Micro-Reinforced Concrete Systems

Supplemental Steel Systems

Epoxy Injections

External and Internal Post-Tensioning Systems (Bonded and Un-Bonded Systems)

Fiber Reinforced Polymer (FRP)

Fabric strengthening systems, also known as fiber reinforced polymer (FRP) systems, consist of woven or stitched carbon and glass fiber fabrics. This innovative combination provides a versatile material suitable for various applications, including strengthening and upgrading weak concrete, masonry, natural stone, and timber structures. Key uses include confinement, shear strengthening, seismic reinforcement, and improving weak substrates.

Crown Waterproofing and Restoration’s craftsmen and technology specialists are skilled in delivering expert advice and efficient FRP solutions. Additionally, Crown Waterproofing and Restoration collaborates with partners to ensure that their strengthening systems are rigorously tested for long-term performance, durability, and strength. Our team excels in the design and installation of FRP systems.

Enlargement and Overlay Systems

Several factors can necessitate the enhancement or restoration of a structure’s capacity. These include updates to building codes, seismic retrofits, changes in building use, design or construction flaws, or capacity loss due to corrosion. At Crown Waterproofing and Restoration, we address these needs using extension and overlay systems that combine specially designed reinforcement with high-flow concrete to create an additional reinforced layer.

To achieve a cohesive concrete enlargement, we focus on surface preparation, the use of specialized materials, and precise shaping techniques to boost or restore structural strength. Our expertise ensures the effective installation of the appropriate overlay systems to meet these challenges.

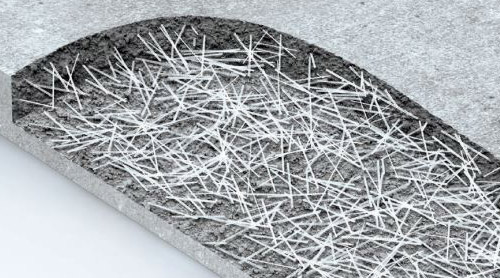

Micro-Reinforced Concrete System

Micro Reinforced Concrete Systems are advanced stabilizing and protective solutions designed to handle extreme loads and absorb energy effectively. Ideal for enhancing structures’ weight limits, ballistic resistance, or impact resistance, these systems can be customized to meet specific performance requirements. The advantages of micro-reinforced concrete systems include:

– The ability to modify design and physical properties to fit project needs.

– A high performance-to-thickness ratio.

– Application as thin as 12 inches.

– Versatility in construction, accommodating various design specifications, dimensions, and orientations.

– Flexible application methods, including both in-situ and precast options.

– Excellent abrasion resistance.

Crown Waterproofing and Restoration’s team of experts ensures the effective application of these technologies to existing structural components. We collaborate with various manufacturers to deliver reliable and proven results.

Supplemental Steel Systems

Composite steel deck slabs have proven effective in buildings with short spans and moderate loads without the need for additional reinforcement. To accommodate longer spans or increased load requirements, reinforcing bars can be used to deepen composite slabs and thicken steel decks in a cost-efficient manner. When properly implemented, these reinforcements enable lightweight, slender composite slabs to cover greater distances, creating more open interior spaces while retaining the advantages of standard composite slabs, such as quicker construction and reduced costs.

Crown Waterproofing and Restoration brings expert knowledge and advanced technology to the application of supplemental steel systems, ensuring a robust and reliable foundation for your building projects.

Epoxy Injections

Epoxy resins are known for their high tensile and compressive strength, making them ideal for structural repairs. These resins, considered to be ‘rigid,’ are commonly used to inject into cracks and voids in reinforced concrete structures. Their low viscosity enables excellent penetration and strong adhesion to concrete, ensuring durable load-bearing capacity. Epoxy resins are versatile and effective for various structural injection needs and perform well in dry to slightly damp conditions.

Crown Waterproofing and Restoration offers expert technology and a range of polymer options. Our skilled craftsmen can assist decision-makers in choosing the most suitable epoxy resin and determining the appropriate quantity for your specific needs.

External and Internal Post-tensioning Systems (Bonded and Un-Bonded Systems)

Post-tensioning is an effective method for significantly increasing load capacity or managing excessive deflection. This technique involves using high-strength steel reinforcement anchored to the structure at specific points. By adjusting the tendon profiles, varying levels of strength and capability can be achieved. In external post-tensioning systems, tendons are installed outside the structural element, often within reinforced ducts to enhance durability and fire resistance. Internal post-tensioning systems are typically integrated into existing members through core drilling or similar methods, focusing on the structural element or new extensions to ensure durability and fire protection.

Crown Waterproofing and Restoration is renowned for its expertise in constructing, rebuilding, and reinforcing specialized structures, consistently delivering high-quality, dependable, and durable solutions.