Waterproofing

Scopes

Below Grade Waterproofing

Damp-proofing

Elastomeric Coatings

Epoxy Floor Coating

Floor Joints & Expansion Joints

Hot and Cold Waterproofing Application

Joint Sealants

Vehicular Traffic Deck and Pedestrian Deck Coatings

Water Repellants

Below Grade Waterproofing

Below-grade waterproofing involves applying membranes and coatings to the foundation walls of a structure situated below street or ground level, forming part of the building envelope. It is also known as below-ground or basement waterproofing.

Effective waterproofing and water management are essential for keeping below-grade areas free from leaks. A knowledgeable project owner should consider which below-grade waterproofing methods and processes will ensure the quality and performance of the finished building.

Various below-grade waterproofing technologies offer different warranty options. Crown Waterproofing and Restoration’s technical team collaborates with owners, contractors, architects, and consultants to choose the most suitable product for each structure, whether it involves hydrostatic or non-hydrostatic applications. Crown Waterproofing and Restoration’s craftsmen are certified applicators for Tremco, Cetco, Grace, and Carlisle.

Damp Proofing

Damp proofing involves applying a coating—typically tar or an unmodified salt mixture—on the exterior side of a structure. Its primary purpose is to prevent the transfer of ground moisture through the concrete. The cured thickness of damp proofing coatings is usually less than 10 mils. This method is often a straightforward and effective solution for reducing moisture infiltration by blocking moisture movement through the concrete’s capillaries, though it does not completely block all water or moisture.

Crown Waterproofing and Restoration’s craftsmen are experienced and certified in applying damp proofing behind various claddings, including metal, wood, brick, and stone veneers. We work with several manufacturers, including Tremco, BASF, Sika, Soprema, Henry Products, Grace, and Carlisle.

Elastomeric Coatings

Elastomeric coating is a thicker-than-paint solution used for exterior walls and roofs above grade. It forms a robust, flexible layer that provides excellent waterproofing. Unlike standard paints or coatings, it can bridge surface imperfections to create a seamless, airtight seal. Suitable for a variety of surfaces such as stucco, concrete, and masonry, elastomeric coatings can be applied to both walls and roofs. Initially applied in a liquid state, it dries to become a flexible, durable layer that moves with the underlying structure.

The team at Crown Waterproofing and Restoration collaborates with owners, architects, engineers, and consultants to select the appropriate technology and colors for elastomeric coatings. Our craftsmen are trained and certified applicators with extensive experience using products from manufacturers such as Tremco, Sika, Neogard, Euclid, and BASF.

Epoxy Floor Coating

Epoxy floor coating is primarily utilized for industrial and commercial flooring applications. It is applied over concrete floors to create a high-performance, smooth, and durable surface.

For optimal adhesion, the concrete must be clean and fully cured before applying the epoxy. Any large cracks or chips in the surface should be patched and repaired, and all grease must be removed prior to coating.

Crown Waterproofing and Restoration brings extensive experience and expertise to both commercial and residential properties, achieving high success rates. Our projects include industrial sites, warehouses, and commercial buildings.

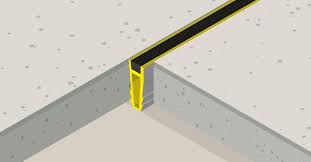

Floor Joints & Expansion Joints

Floor joints are essential for various applications in both horizontal and vertical structures. These joints accommodate movement caused by temperature fluctuations, wind, and structural settlement, and are typically placed centrally to prevent cracking.

Expansion joints are designed to manage stress on building materials due to factors such as thermal expansion and contraction from temperature changes, sway from wind or seismic events, and deflection from static and live loads. Proper expansion joint transitions are crucial for maintaining a secure, safe, and cost-effective building envelope. Factory-fabricated transition assemblies help ensure seal continuity at changes in plane and direction, as well as between different expansion joint systems.

Crown Waterproofing and Restoration’s craftsmen are certified applicators for Emseal, MM System, Willseal, and Balco structural expansion joints, suitable for both vertical and horizontal joints ranging from 1 to 8 inches or more.

Hot and Cold Waterproofing Application

Hot Waterproofing Application Hot rubberized waterproofing membranes are fluid-applied coatings made from asphalt and modified rubber polymers with mineral stabilizers. These systems create seamless, monolithic membranes suitable for large surface areas.

Crown Waterproofing and Restoration’s craftsmen are certified applicators with specialized expertise in hot-applied systems. We handle a range of applications including tunnels, parking decks, balcony decks, roofs, green roofs, podium decks, planters, split-slab systems, and plaza decks.

Cold Waterproofing Application Cold fluid-applied insulation membranes are used in construction where traditional sheet insulation or hot-applied membranes are impractical. These flexible membranes can be applied both vertically and horizontally, offering long-lasting protection when properly installed.

Crown Waterproofing and Restoration’s technicians are fully trained and certified in applying cold-applied systems. We specialize in areas such as balconies, pool decks, amenity spaces, private terraces, and back-of-house rooms.

Joint Sealants

Joint sealants are designed to minimize both surface water infiltration and the entry of incompressible materials into the joint system. They also help reduce the risk of dowel bar corrosion by preventing de-icing chemicals from penetrating the system. Although joint sealants can significantly reduce water intrusion, modern vacuum tests have demonstrated that no sealant can provide a completely watertight barrier.

The benefits of joint sealants include protecting against temperature fluctuations, soil, rocks, and other debris. Incompressible materials in the joint during thermal expansion can lead to localized issues such as cracks or failure. Joint sealants also help mitigate the effects of de-icing chemicals used in colder climates by limiting water intrusion. Since at least the 1970s, the advantages and cost-effectiveness of joint sealing have been widely discussed. Today, the use of concrete pavement joint sealing is often tailored to specific project needs, considering factors such as facility type, pavement design, and other conditions.

Crown Waterproofing and Restoration’s technicians are highly trained and experienced in applying both urethane and silicone sealant technologies.

Vehicular Traffic Deck and Pedestrian Deck Coatings

Vehicular Traffic Deck Coatings: These coatings are designed for surfaces exposed to heavy vehicle traffic, such as garages, decks, ramps, stadiums, and arenas. They provide a strong, durable solution capable of withstanding the constant movement of vehicles.

Pedestrian Deck Coatings: Ideal for footbridges, walkways, paths, mechanical spaces, arenas, and balconies, these coatings are formulated to endure frequent foot traffic and provide long-lasting protection.

Crown Waterproofing and Restoration’s craftsmen bring advanced expertise and technology to every project. We also partner with leading manufacturers including Tremco, Sika, Grace, Cetco, Carlisle, BASF, DOW, and Euclid.

Water Repellents

Integral water repellents are polymeric liquid admixtures added to concrete masonry units during production to reduce water wicking. This makes the masonry hydrophobic by decreasing capillary suction and minimizing water movement through the material. For optimal performance, these water repellents should also be integrated into the mortar on-site, as well as into any masonry elements like precast lintels. The use of water repellents in construction offers numerous benefits, including resistance to water migration, improved control of efflorescence, enhanced mix fluidity, and better pigment dispersion.

Crown Waterproofing and Restoration’s craftsmen possess extensive expertise in waterproofing construction, ensuring superior quality and highly effective results.